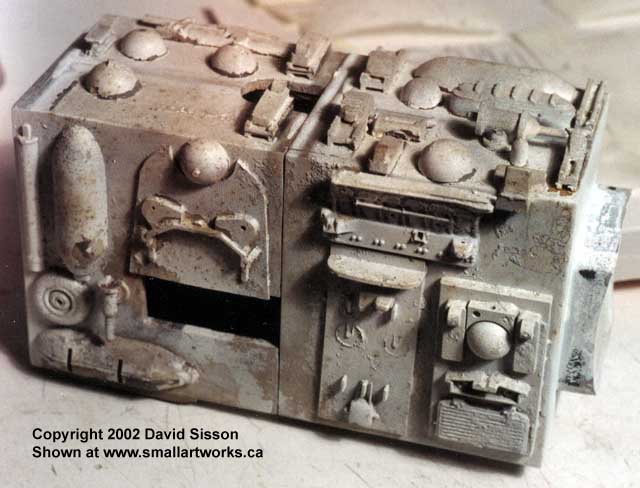

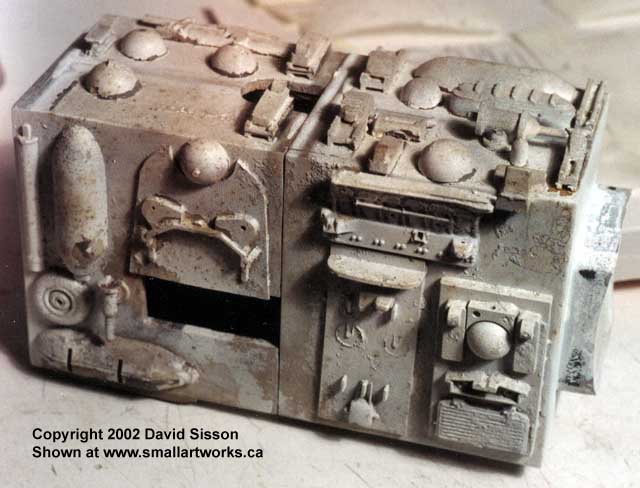

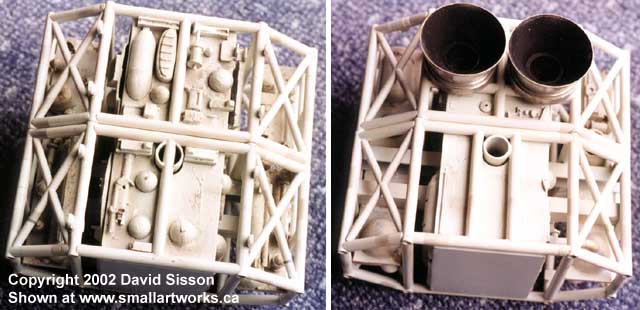

Above:

The front interior corridor with the "kitbashed" detailing. Parts from

plastic model kits were randomly glued in place to create texture.

Detailing on these sections is fairly crude

and comes from a variety of model ship and aircraft kits. Any sort of flat

kit parts, bulkheads, instrument panels, decking etc, is simply stuck on

with no attempt to blend or disguise them. One disappointment is that there's

no doorway detailing at the end next to the passenger pod, just the

faint drawn-on outline of a hatch.

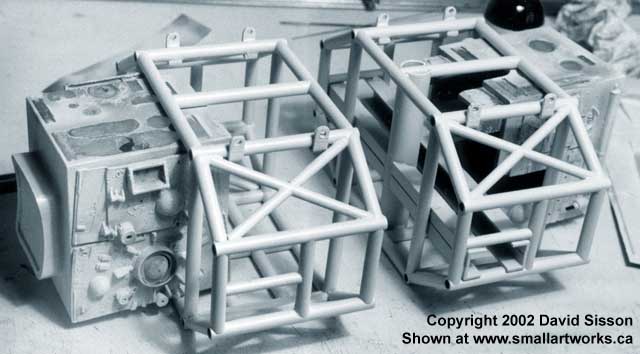

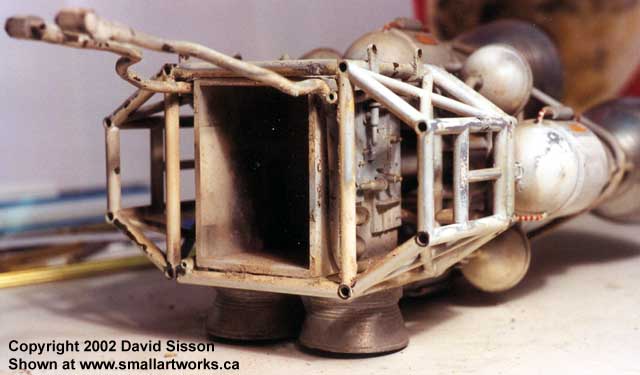

With the two halves pushed back together

the kit parts on the top and bottom were gently tacked back into position

and the unit was repainted using coats of grey and white primer followed

by a bit of airbrushed weathering.

The kit parts were again removed to allow

for the reinsertion of the section back into the repainted brass cages

and then the parts were permanently glued back down. The two side shelves

were now put back into position, apart from a little bit of cleaning I

decided to leave them alone as I saw no reason to alter or repaint them.

From the start I had decided to try and

leave some parts of the model untouched to ensure that it didn't start

to look like a replica, the idea was to repair major damage (large cracks,

split frame etc) get rid of the terrible paintwork and return it to a decent

condition but not to try and remove every single blemish. The models 29

years old and the knocks it has received are like scars tracing its history

and make the model more interesting to look at, toning them down is fine

but I didn't want to remove them completely.

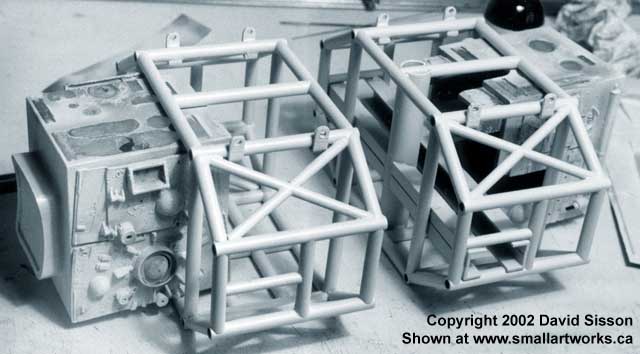

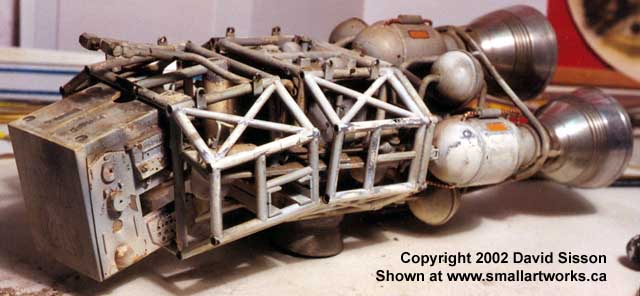

The Front cage had been easy with only

a couple of breaks to fix up but the rear had a lot of damage and was in

danger of falling apart in places .

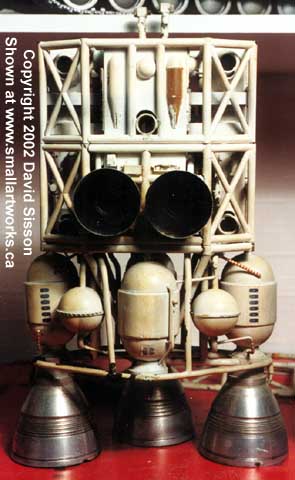

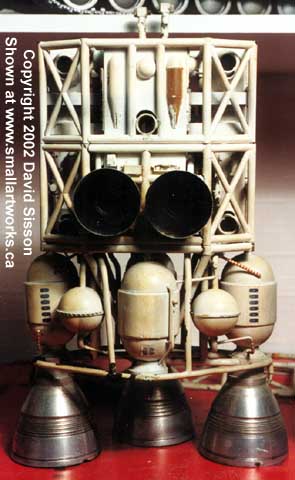

The aluminium engine bells are just held

in place by allen screws and during the first series could easily be removed

(you can see one dropping off during the crash landing scene in The Last

Sunset) but with the modifications for series two they are locked in place

by the gas feeder tubes that pierce the sides near the base, however three

of the connections are broken so these bells could be removed during the

restoration process.

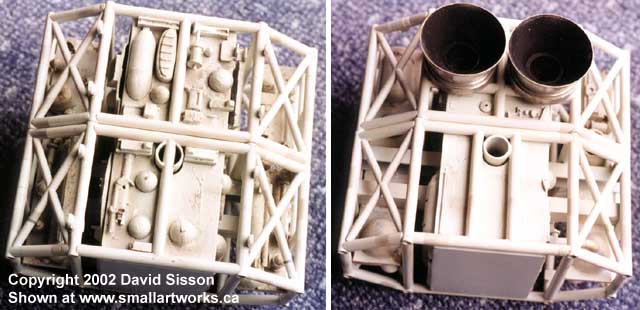

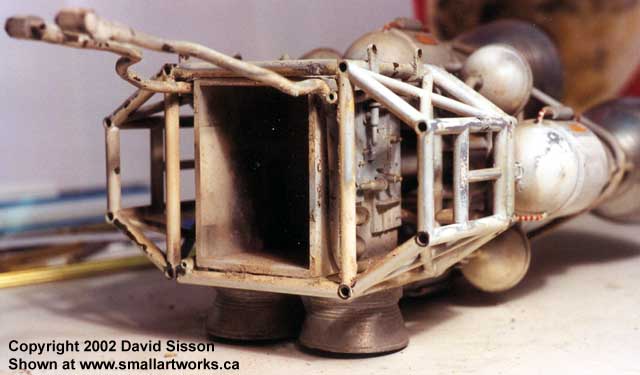

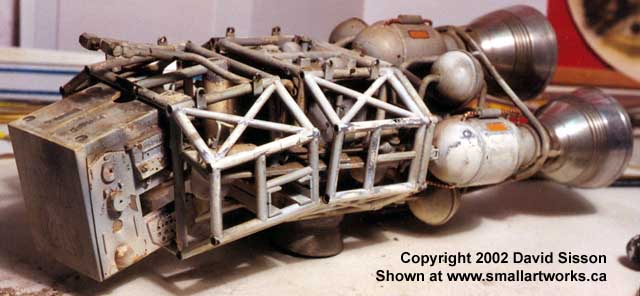

Splitting this section again began with

the removal of all the kit parts on the top and bottom panels however the

process was made more difficult by the gas feeder tubes which extend through

the cages. These tubes begin with two small inlet valves connected to copper

pipes that reside between the pipework of the spine. One tube extends straight

back to the ring pipe, which encircles the base of the four engines, connecting

at the top right side. The other works it's way downwards and connects

to the ring at the lower left side with two further dummy pipes added (bottom

right/top left) to balance out the design.

Very slowly the pieces came apart, progress

was held up by the two side shelves that had a lot more detailing on them

which jammed between the cage pipework and included connecting tubes to

the central corridor section.

As a result I had to disassemble parts

of the shelves before they would come out and stick those bits on more

double sided tape on more bits of card covered in more diagrams.

Yikes!

What a mess!

There was a point when I began to

wonder if it was all going to go back together again..........

Continued...

|